About Abezen Shoten

Abezen Shoten

Abezen Shoten is located in Shiogama city, Miyagi prefecture, a city widely known as a major fishing port with large catches of fresh fish caught off the coast of Sanriku, one of the three greatest fishing grounds in the world. As the name suggests, Shiogama was famous for its production of salt ("Shio" means "salt"). The high-quality water in Shiogama contributes to the number of sake breweries

Fish, salt, and water are three key ingredients for making fishcake. Shiogama had all three of them to prosper as one of the most renowned production districts of fishcake in Japan.

We have been producing fishcake in Shiogama city with all three key factors since 1926. We especially take pride in making not only plain-type "Satsuma-age (deep-fried fishcake)", but also a variety of products with fresh vegetables and seafood.

We were the first company to start selling easy-to-use sets of ingredients for "Oden (Japanese style hot pod)" in the industry. We have been producing a variety of quality products for use all over Japan.

Fishcake

Kamaboko (fishcake) is a traditional Japanese food made from fish paste that was invented over 900 years ago. Different recipes exist, such as steaming, broiling, and deep-frying. "Satsuma-age", our main sales item, is made by deep-frying the fish paste, which gets carefully kneaded and shaped by our skillful staff.

Our Policy

1. Connoisseurship (purchasing) = Pursuit of deliciousness

We only use ingredients that go through a set of tests in our lab and meet the standards after obtaining approvals from the stock department, quality assurance team, and product design committee.

Regarding the fish paste and ingredients used for our Oden sets, we inspect the suppliers and see for ourselves if the ingredients are produced under proper quality control. However, we focus on how "delicious" the ingredients are in all aspects.

2. Skills = Traditional recipes + extra something

Although recipes for making fishcakes have already been established, they may vary depending on the manufacturer and the type of fishcakes they make.

Since the foundation, we have been preserving the traditional recipes and skills to pass on the good old taste while flexibly taking in new recipes and ideas to achieve better creativity and quality.

3. Sincerity = Pleased customers

"Producing fishcake from the perspective of our customers"

As a matter of fact, we can maintain our business because of our customers who enjoy our products. Based on that, we hope to keep striving to contribute to the society through fishcake manufacturing.

Food Safety

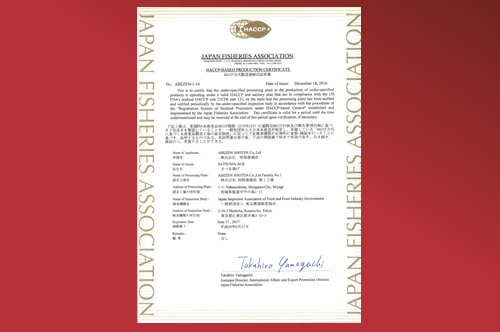

We have implemented the HACCP System because we truly care about the safety of our products.

We have been implementing modern equipments and a stringent system of quality control to further improve the safety of our products.

Moreover, we implemented the HACCP System in 1999, a food sanitation control technique developed for the production of space foods, and have been passing the semiannual inspections since then.

Our fishcakes are produced under a strict quality control.

About the HACCP System

The HACCP System is a brand new method of managing food sanitation control that improves food safety.

It was developed by Pillsbury Company in order to achieve safety of space foods in the 60's. Before the HACCP System came, food safety inspections were done by taking only certain parts of the products for inspection, however, this could not wipe away the risk of distributing products with unexamined parts and causing cases, such as food poisoning.

On the other hand, the HACCP System predicts any possible risks throughout the entire manufacturing process, and specifies Critical Control Points (CCP) to prevent any risks (or to reduce them). By continuously observing and recording CCPs, it makes it possible to take quick actions to solve problems and avoid distributing failed products.

The Codex Alimentarius Commission, established by FAO/WHO, introduced a guideline, and has been promoting it to countries all over the world.

Achieving "Safety" and "Quality" by preparing a sanitized environment

We strive to achieve safety and quality control by equipping the chill rooms with air filters, implementing stringent quality inspections on fully automatic production lines, and placing a sanitary inspection room in the company to examine the products.

Also, we use no preservatives, and do our best to use less additives, such as chemical seasoning, as possible to pursue the real taste that matches the needs of people of today, and to produce healthy products.

Contact Us

E-mail: contact@abezenshoten.comHead office: 1-11 Nakanoshima, Shiogama City, Miyagi 985-0015, Japan

Phone: +81-22-364-2155